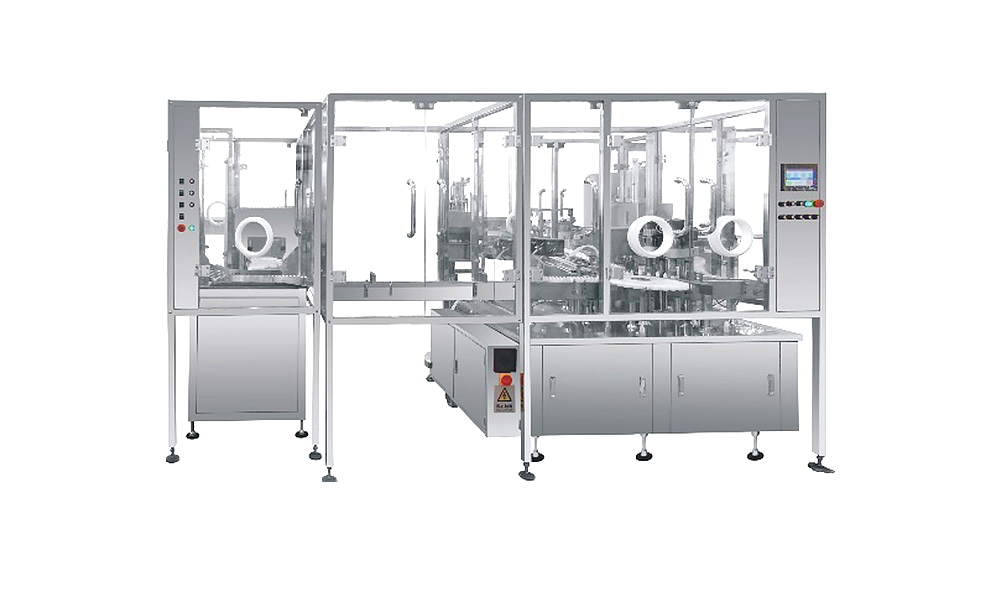

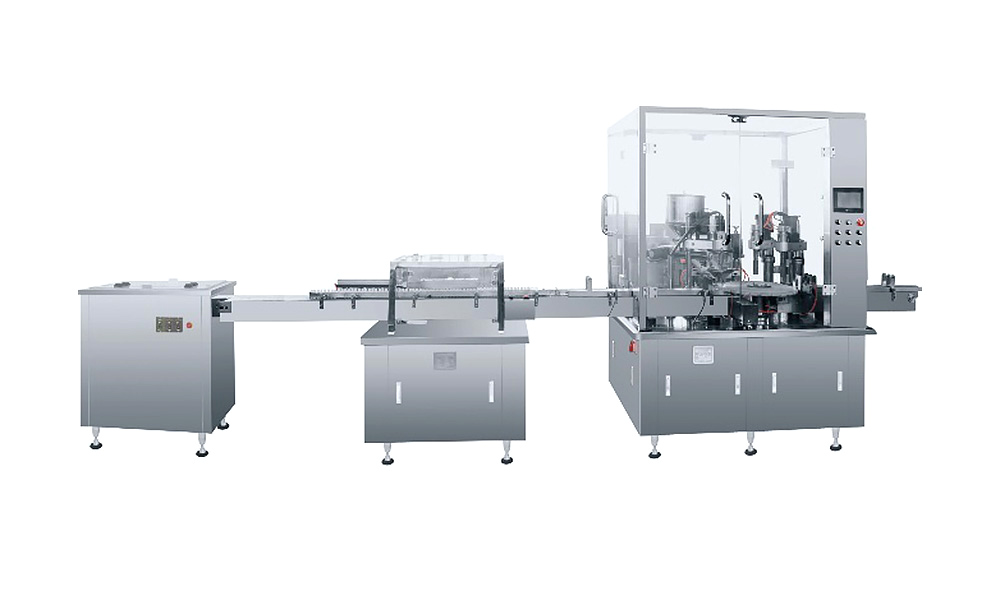

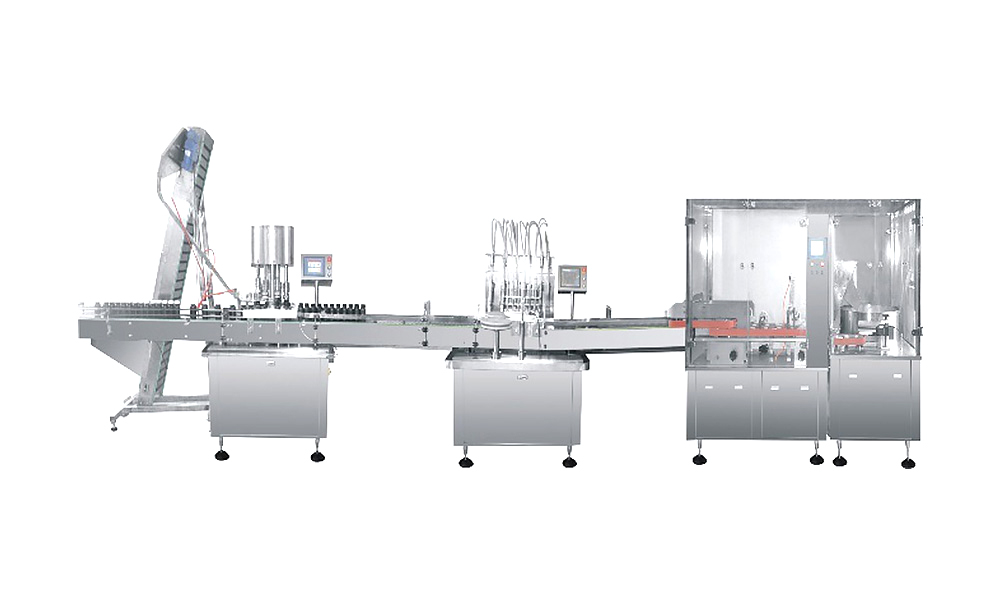

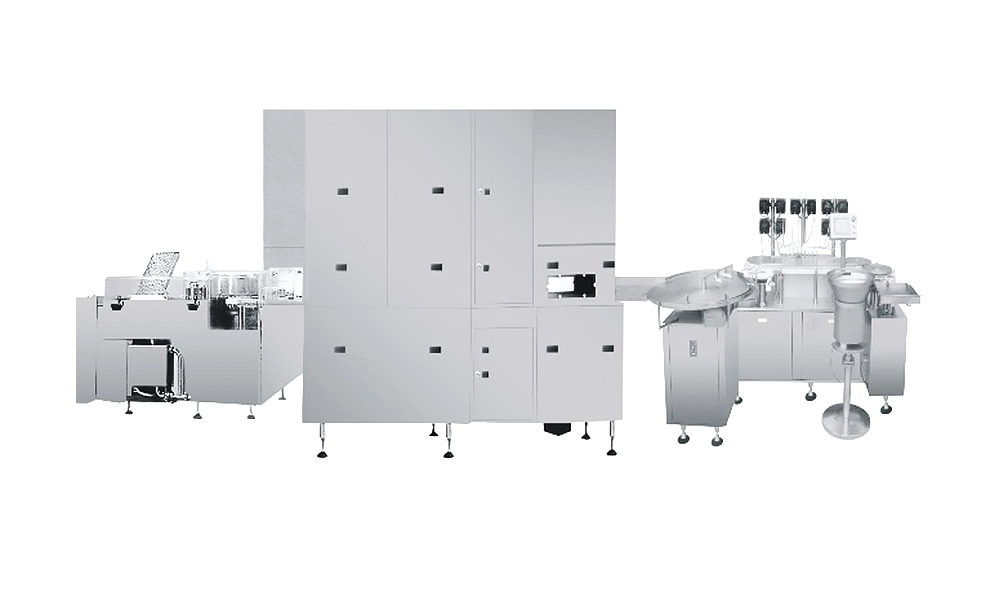

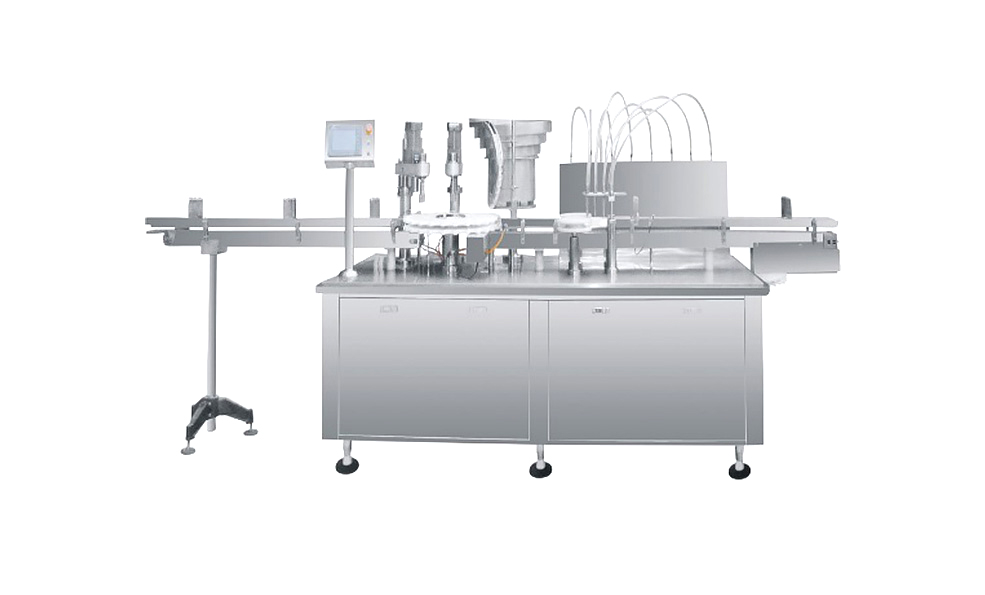

1, the entire line of slender structure, can be a single side through sterile gloves to complete all operations, do not destroy the clean environment, fully meet the requirements of the national version of GMP.

2, each function area is equipped with RABS system, ensure no cross contamination.

3, the whole machine PLC control, touch screen operation, frequency control, fault alarm, fault protection function, automatic counting function.

4, ion wind dust, dust collection automatic discharge, composite blowing blowing down the needle alone, without cross contamination, ensure blowing effect.

5, the use of high precision ceramic pump filling, separate servo system control, the filling amount of each filling head can be adjusted at any time in the man-machine interface. High accuracy, good stability, long service life.

6, the filling of advanced control technology, to ensure the filling no shock, no splash, no bubble, no leakage generated.

7, multi point optical fiber monitoring, has no bottle filling, torinese, without external cover, no plug capping function, with automatic rejection function.

8, the use of mechanical hand plug, plug, cover, cover, accurate and reliable action, high pass rate.

9, the specification of the use of limited positioning design, installed after no need to adjust the replacement, no special tools to replace. All specifications unified numbering and laser engraving. Equipment maintenance, repair, replacement parts for convenient and quick.

10, alone with the material buffer tank, can be achieved online cleaning and heat sterilization.

English

English 简体中文

简体中文